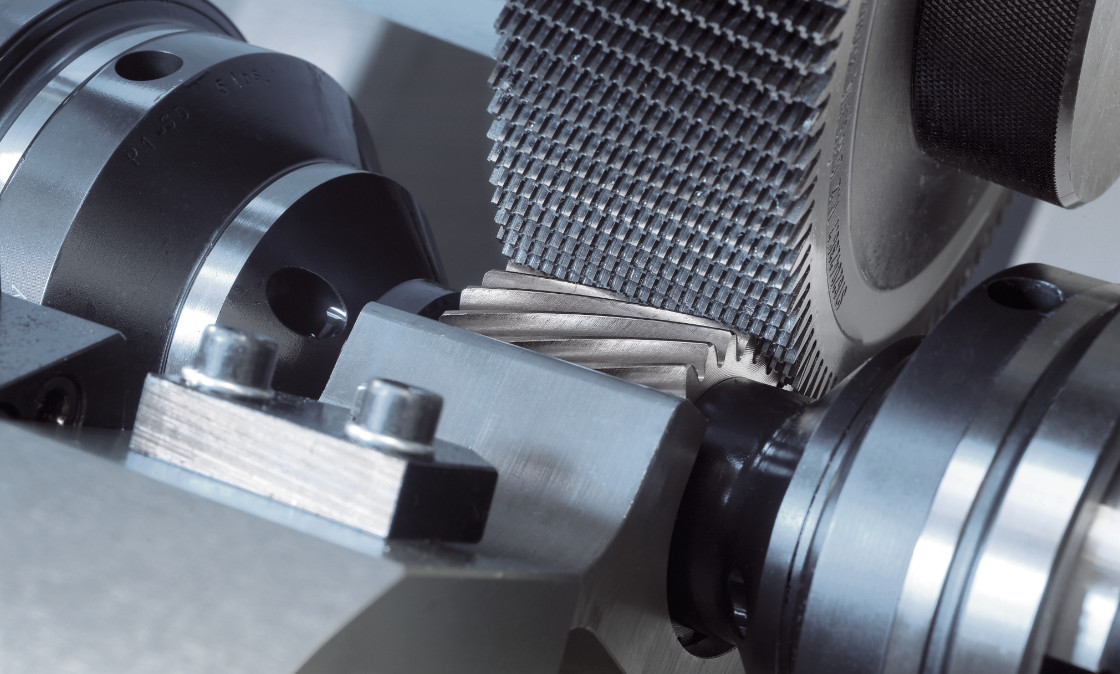

A shaving cutter is a very precise tool that looks like a disc-shaped helical gear with slots that run down the flank to form cutting edges. In this manner, to plan and produce shaving cutters, complete work gear subtleties and shaper subtleties, assuming accessibility, are required. In order to find out the quality shaving cutter, the buyer has to go with the help of gear shaving cutter manufacturer. It is committed to offering a huge range of tools with special features and support.

Shaving Cutters from the company include conventional gear shaving cutters, diagonal gear shaving cutters, and underpass gear shaving cutters. Normally, the cutters are delivered in PCD scopes of 150 to 300 mm, with the proper face width and bore-by details—gear shaving cutters designed to meet the finishing requirements of work gears. To support the smooth completion of the flanks of the works, the helix point of its teeth contrasts with that of the work gears.

The process:

Gear shaving lessens tooth profile, record, and lead blunders on work gears made by hobbing and molding activities and fundamentally works on a superficial level completion of the stuff flanks—the tapered or crowned tooth shape required to avoid end bearing conditions produced by shaving.

I am shaving finished by quickly pivoting the shaving shaper in a nearby lattice with the work gears on the stuff shaving machine. The bleeding edges eliminate chips, or fine hair, by clearing over the flanks of the work gear during the pivot.

The stuff driven by the shaper between the two live focuses and responds transitionally, by the plunged technique. It is feasible to accomplish a serious level of surface completion and fewer mistakes in the record, helix point, tooth profile, and whimsy by shaving stir gears with hardness up to 30 RC on the stuff teeth. The right cutting oil is utilized for the shaving system.

Benefits:

While sending high power at rapid, gear commotion is enormously decreased because of enhancements in surface completion and a decrease in different stuff tooth blunders. Also, the cog wheels’ life broadened. Shaving a tooth to a tightened or delegated shape decreases surface grouping of the tooth end burden and raises the well-being factor.

Shaving happens rapidly and demands almost no working investment. The cutter can finish a large number of high-quality gears because it sharpens once more, making this the fastest and most cost-effective method.

Deliver accurate gears:

As a result, the automotive industry can make a lot of highly accurate gears at a high production rate and relatively low cost by gear shaving. Complete subtleties are expected to plan and make shaving cutters since gear shaving cutters are made to meet the completing prerequisites of work gears explicitly.

For finishing gears that have been pre-shaped or hobbled, Gear Shaving Cutters are ground precisely. All gear-shaving cutter suppliers review and lead test outlines. These instruments are sensitive, so they accompany lead test outlines and examinations. It becomes simple to activate at all times with better comfort.