The hydraulic torque wrench is an advanced version of the traditional handheld torque wrench. A hydraulic torque wrench is a calibrated device that can measure the torque used to secure and achieve the desired tightness or loosening of a bolt. It was invented by George A Sturdevant in 1968 and ever since. They are also used in a cross-section of prominent industries such as transportation, field construction, and oil and gas exploration. Hydraulic torque wrenches are used with well-lubricated bolts or fasteners. Hydraulic torque wrenches are lightweight and have quiet operation compared to pneumatic wrenches. These wrenches have an accuracy of +3% and are long-lasting. Ideal for industries and applications using large bolts where a high level of torque accuracy is required.

What Is A Hydraulic Torque Wrench?

A hydraulic torque wrench is a bolting tool specially designed for applications where space is limited or a high torque output is required and is mainly used to tighten or remove large bolts. Mainly used in shipbuilding, petrochemical, construction, electric power, mining, metallurgy, and other industries. The hydraulic wrench is a very important torque machine for installing and removing large bolts. Easy to use and lightweight, and the torque provided is enormous and precise. The repeatability of the peak torque is about 3%. The hydraulic torque wrench price in indiawill be very affordable and also it will a good quality.

Who Invented The Torqueing Tool?

The hydraulic wrench first appeared in the 1960s and was later invented by George Sturdevant in 1968. Later, engineers carefully studied the physical principles of bolt-tightening tools. Therefore, the measurement method and force used are improved to be consistent and accurate. Combined with advances in technology and their use by bolt tool manufacturers, Today’s torque wrenches were also created.

How Do Bolting Tools Work?

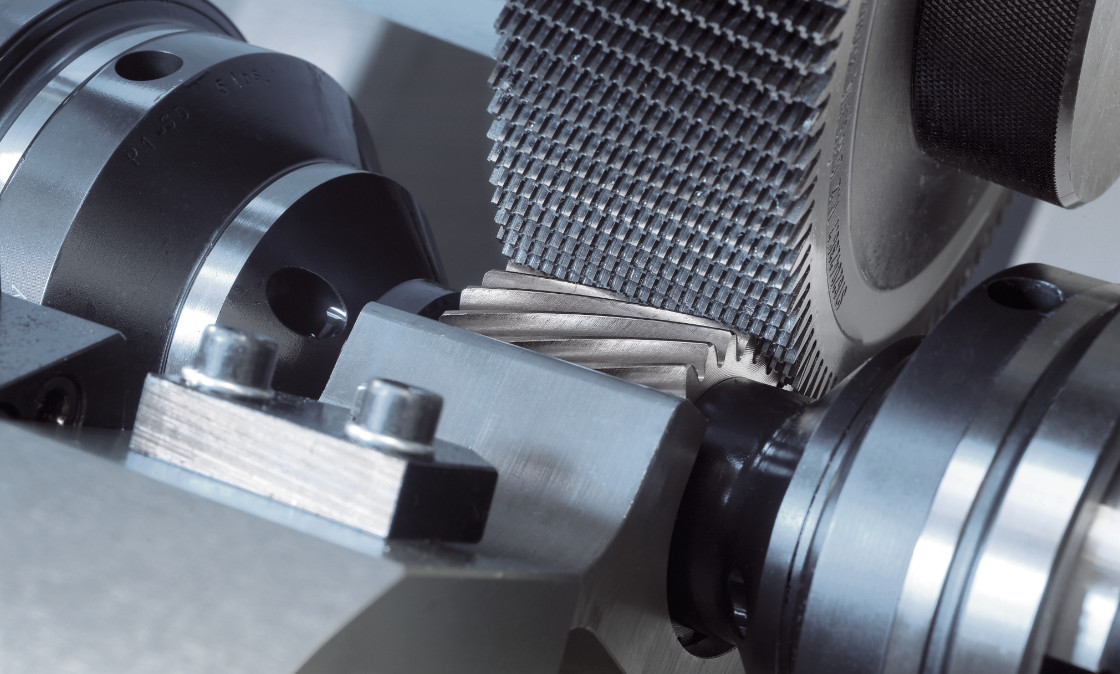

The design of the torque machine uses the large leverage generated by the hydraulic piston and high-pressure hydraulic power from a pneumatic or electric hydraulic pump. The hydraulic piston is connected to the gear wheel by a series of reaction pins that allow it to engage the gear teeth in advance mode to rotate the nut or bolt head. It is then released during the piston retract to reassemble with the next piston. All hydraulic power wrenches operate under hydraulic pressure up to 700 bar, with heavy-duty double-action hydraulic pistons. Easy to use and fast and can be used to tighten or loosen nuts/bolts with precision. In general, hydraulic torque toolare mainly used for installing and removing bolts greater than one inch in diameter. Driven by hydraulic pressure and provides high torque. The maximum output torque of the bolt device can reach 140,000Nm.

Type and Mechanism:

Each of them is designed based on the area in which it is specified to be used. Torque is the product of the rotational force applied to the bolt and the distance from the center of the torqued object to the tool clearance. The product of force and distance is measured in pounds, feet, or Newton meters. The torque of a hydraulic wrench is set differently than other electric wrenches. Due to the method of use

- These wrenches create torque using only hydraulic pressure.

- They have their moving mechanism.

- Including a system that can accurately measure the torque used.