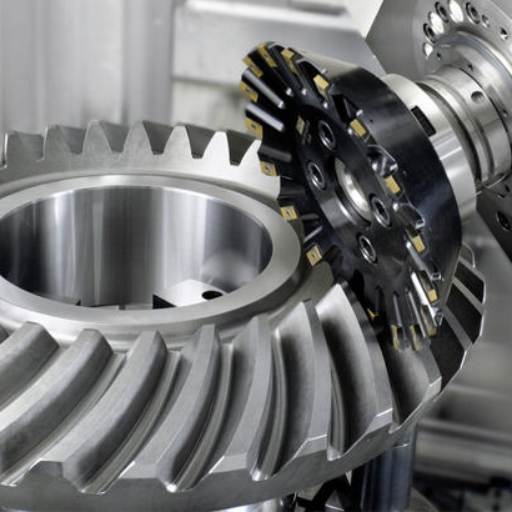

The production of accurate gears and complex profiles relies heavily on the quality of the cutting tools used in milling operations. Among the most important of these tools are the gear milling cutter and various form milling cutters. These specialized cutters enable manufacturers to generate precise tooth shapes, splines, and custom contours with repeatable accuracy across a wide range of materials.

As industries demand quieter transmissions, higher efficiency, and longer component life, the role of advanced milling cutters has become more significant than ever.

The Importance of Milling in Gear Production

Milling remains one of the most versatile methods for producing gears, especially for small batches, prototypes, and repair work. Unlike hobbing machines that are dedicated to high-volume runs, a gear milling cutter can be used on conventional or CNC milling machines, providing flexibility to workshops of all sizes.

Form milling cutters extend this capability further by allowing the creation of non-standard profiles such as:

- Splines and serrations

- Ratchet forms

- Timing pulley teeth

- Custom industrial profiles

This adaptability makes milling cutters essential tools in toolrooms and specialized gear shops.

What Is a Gear Milling Cutter?

A gear milling cutter is a form-relieved tool whose cutting edges mirror the space between gear teeth. By indexing the workpiece after each pass, the cutter gradually generates the full gear around the blank. Sets of cutters are usually supplied for different tooth ranges to maintain accurate involute geometry.

Key features of a high-quality gear milling cutter include:

- Precisely ground tooth profile

- Correct rake and relief angles

- Uniform pitch between teeth

- Stable heat treatment

- Compatibility with various modules and DP standards

When these factors are controlled, the cutter can produce gears that meet strict DIN or AGMA requirements without additional finishing.

Understanding Form Milling Cutters

Form milling cutters are not limited to gears alone. They are designed to reproduce virtually any required shape on a component. The profile of the cutter is the negative of the desired workpiece form, allowing accurate duplication in a single pass.

Common applications include:

- Involute and non-involute gears

- Keyways and special slots

- Convex/concave radii

- Dovetail and angular forms

- Aerospace and hydraulic components

Manufacturers often rely on custom form milling cutters when standard tools cannot achieve the required geometry.

Materials and Construction

Modern cutters are produced from a variety of substrates:

- High-Speed Steel (HSS) – Tough and economical

- Cobalt HSS – Better hot hardness

- Powder Metallurgy HSS – Superior wear resistance

- Carbide – For high-speed CNC applications

Advanced coatings such as TiN, TiAlN, and AlCrN further improve the life of gear milling cutters by reducing friction and heat generation.

Benefits of Quality Milling Cutters

Using professional-grade gear milling and form milling cutters provides tangible advantages:

- Accurate tooth geometry and spacing

- Excellent surface finish

- Reduced secondary operations

- Longer tool life

- Lower cost per component

- Flexibility for small and medium batches

These benefits are particularly valuable for maintenance workshops and custom machinery builders.

Selecting the Right Gear Milling Cutter

Proper selection depends on several parameters:

- Module or Diametral Pitch

- Pressure angle

- Number of teeth on the gear

- Work material hardness

- Machine rigidity and spindle speed

- Required accuracy level

Consultation with experienced suppliers, such as those represented on sstools.net/milling-cutters/, helps users choose the most suitable cutter for each project.

CNC Milling and Modern Requirements

With the rise of CNC machining, gear milling cutters are now used with advanced strategies such as:

- Multi-axis interpolation

- Optimized feed control

- Dry or MQL cutting

- High-speed carbide milling

Form milling cutters designed for CNC environments allow manufacturers to combine precision with productivity.

Maintenance and Re-sharpening

To maintain accuracy, cutters must be cared for properly:

- Regular inspection for wear or chipping

- Professional re-sharpening without altering profile

- Correct storage to prevent damage

- Use of appropriate coolants

A well-maintained gear milling cutter can be resharpened multiple times, greatly reducing tooling costs.

Industries That Depend on These Cutters

Gear and form milling cutters are used across numerous sectors:

- Automotive and EV components

- Industrial gearboxes

- Agricultural machinery

- Textile and printing equipment

- General engineering and toolrooms

- Aerospace prototypes

Their versatility makes them indispensable wherever customized profiles are required.

Partnering with a Reliable Supplier

Choosing the right tooling partner ensures access to:

- Standard and custom cutter designs

- Technical assistance with profiles

- Consistent quality and delivery

- Re-sharpening and coating services

Suppliers with deep experience in both gear milling cutters and form milling cutters can support projects from concept to production.

Conclusion

The gear milling cutter and form milling cutters remain fundamental tools for creating precise gears and complex profiles in modern manufacturing. Their flexibility, accuracy, and cost-effectiveness make them ideal for both prototype development and regular production.

By sourcing these tools from specialized providers like those featured on sstools.net/milling-cutters/, manufacturers can achieve reliable results, shorter lead times, and superior component quality—essential ingredients for success in today’s competitive engineering landscape.